MITUTOYO - Varifocal : Lens TAGLENS | JSR GROUP

TAGLENS

Ultra-deep focus eliminates the limitations of the conventional lens

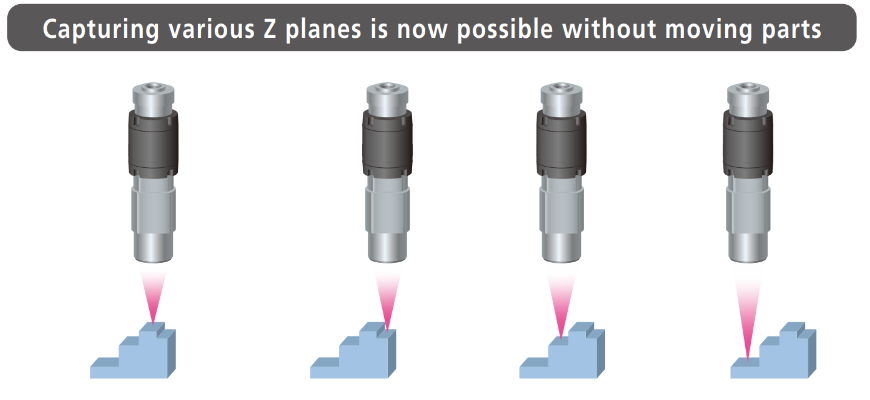

Optical imaging can be complicated: observation target distance may vary due to a tilt or complex geometry, target may be in motion, and more than one target may be captured in the frame. In such situations, TAGLENS keeps the entire imaging volume in focus resolving the inevitable problem of the conventional optical systems. Omnifocal shooting provides improved productivity through enhanced imaging efficiency and reduced costs.

SPECIFICATIONS

|

TAGLENS-T1 Ultra-high-speed varifocal lens.A dedicated controller and a control software TAGPAK-C are offered as a standard product. |

|

|

Video Microscope Unit VMU-T1 Microscope unit for configuring a varifocal optical system by incorporating the TAGLENS-T1, the objective lens and the camera. |

|

|

Illumination light source: Pulsed Light Source (PLS) In combination with TAGLENS-T1, this ultra-high-speed LED pulsed light source device captures focused images at the desired height as well as focus stacking, etc. |

*1 Lighting frequency: 70 kHz, Input pulse width: 80 ns Light guide: 2 m long, multicomponent glass fiber |

APPLICATIONS

TAGLENS gives prompt solutions to problems in inspection and observation. Some application examples using TAGLENS are introduced hereafter.

| Inspection of electronic / precision components |

|

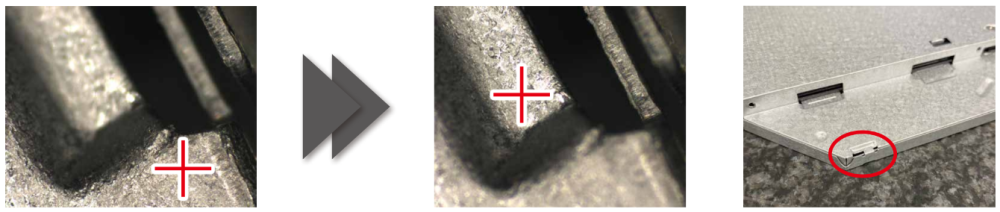

Problem ・ Inspection time for electronic and precision parts, etc., needs to be reduced. Solution ・A large depth of focus even in a high-magnification observation eliminates the need for focus Proposed Functions ・EDOF ・Auto Focus |

Example: Semiconductor flaw inspection Eliminates the need for focus adjustment, thus achieving effective inspection. |

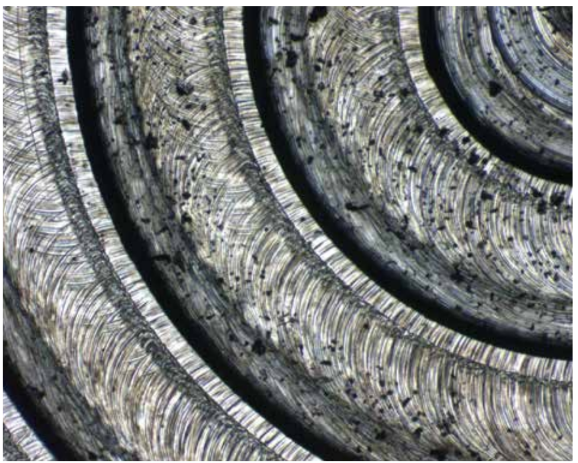

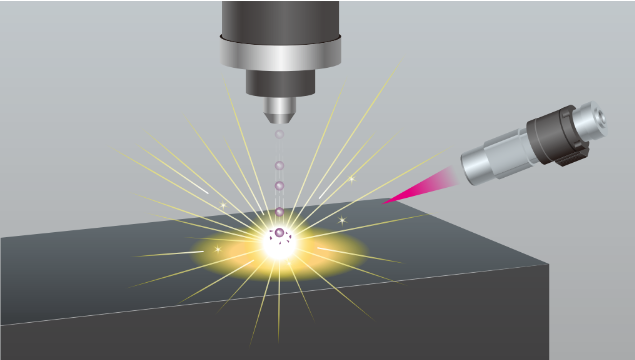

| High-speed imaging |

|

Problem ・Instantaneous shooting of a crash test results in defocusing of scattered chips. Solution ・Allows shooting of deep images at a time, thus capturing all scattered chips. Proposed Functions ・EDOF ・Focus Stacking |

Example: Crash test |

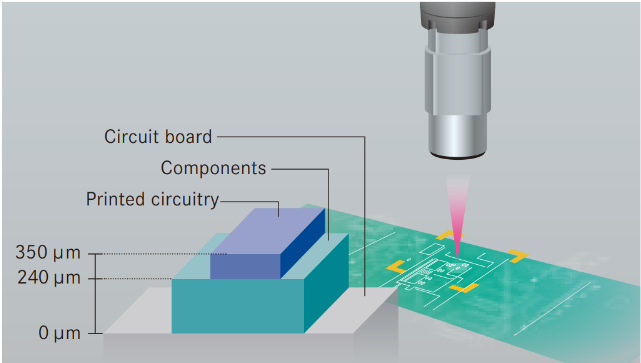

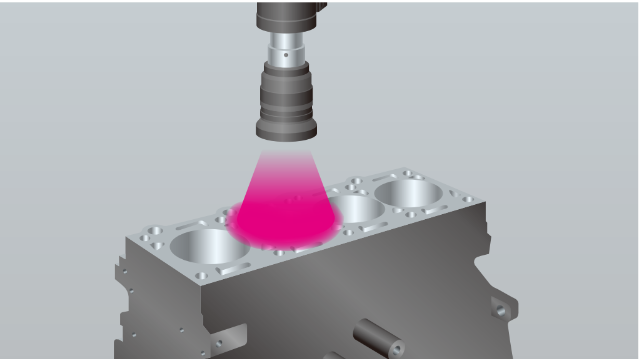

| Machine vision |

|

Problem ・ Observation target heights and distances require the use of robots, leading to a complex and expensive system. Solution ・Excellent focus expansion effects and long scan range. Proposed Functions ・Auto Focus ・Multi Focus ・Mixed Image |

Example: Inspection of large parts for defects Distant observation is possible with a machine vision lens |

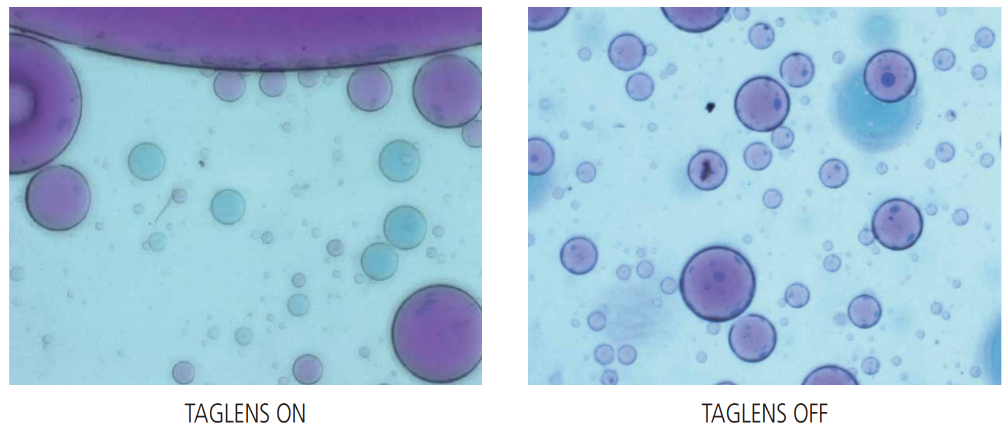

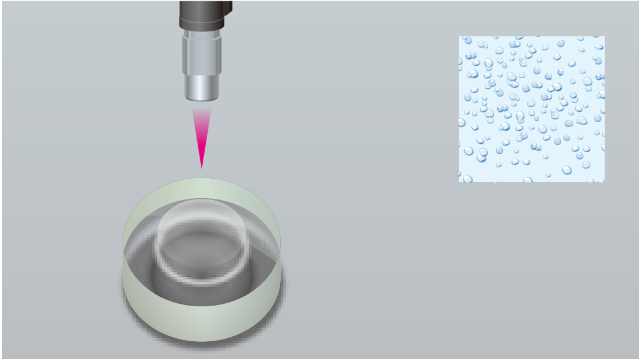

| Measurement of minute particles and floating matter |

|

Problem ・The 3D positions of particles cannot be captured. Solution Proposed Functions ・Auto Focus ・Multi Focus ・Mixed Image |

Example: Observation of minute bubbles in glass / liquid Absolutely allows observation of target objects with a large depth of focus. |

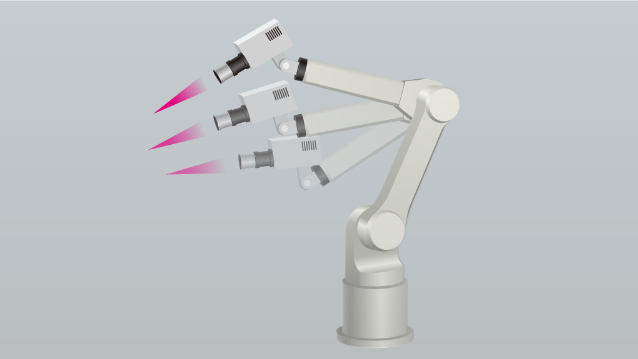

| On a robot |

|

Problem ・It takes time to observe a workpiece from various angles with the camera mounted on a robot arm. Solution ・The large depth of focus eliminates the need for focus adjustment and allows observation from various angles, thus contributing to time-saving of observation. Proposed Functions ・EDOF ・Multi Focus ・Mixed Image |

Example: Inspection using a robot. |

ABILITY

TAGLENS, the breakthrough ultra-fast varifocal lens, will always keep your sample in focus, enabling the highest observation and measurement efficiency.

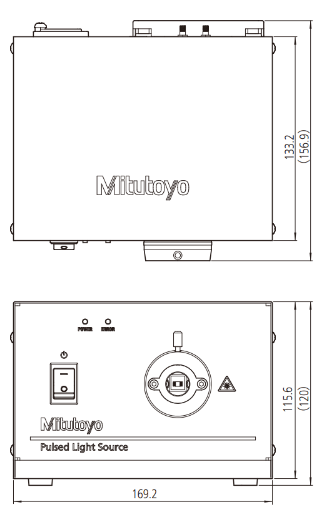

Improve inspection efficiency using TAGLENS with its ultra-wide focus range

EDOF (Extended Depth of Focus)

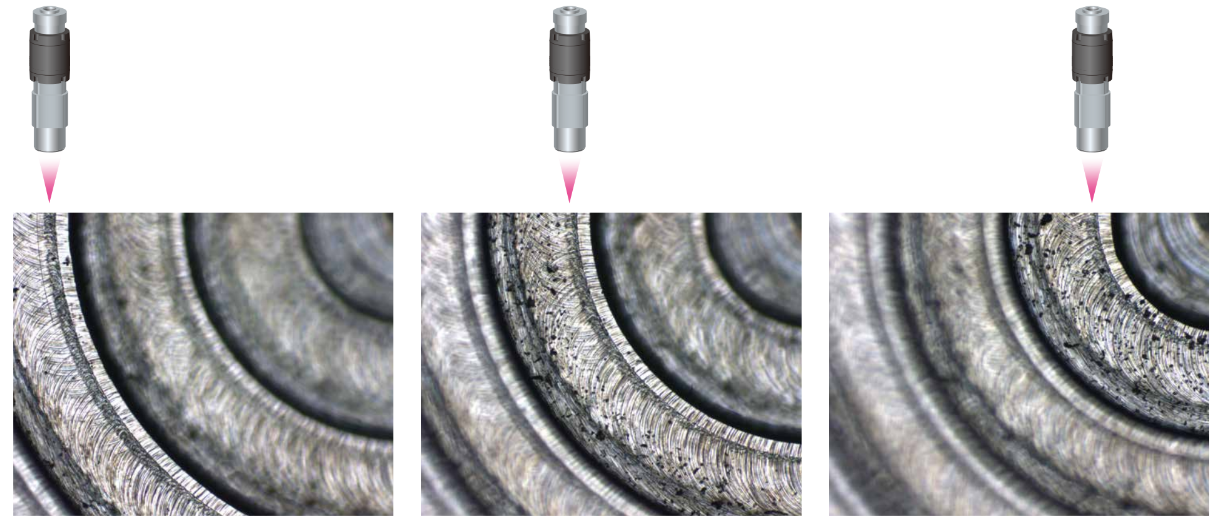

The focus range is variable without changing the camera position

Until now, imaging of objects with differing heights and depths was performed by taking multiple photographs while moving the camera vertically (Z-axis motion). In contrast, TAGLENS allows simultaneous probing of multiple heights or depths. Moreover, a captured image is displayed in real time.

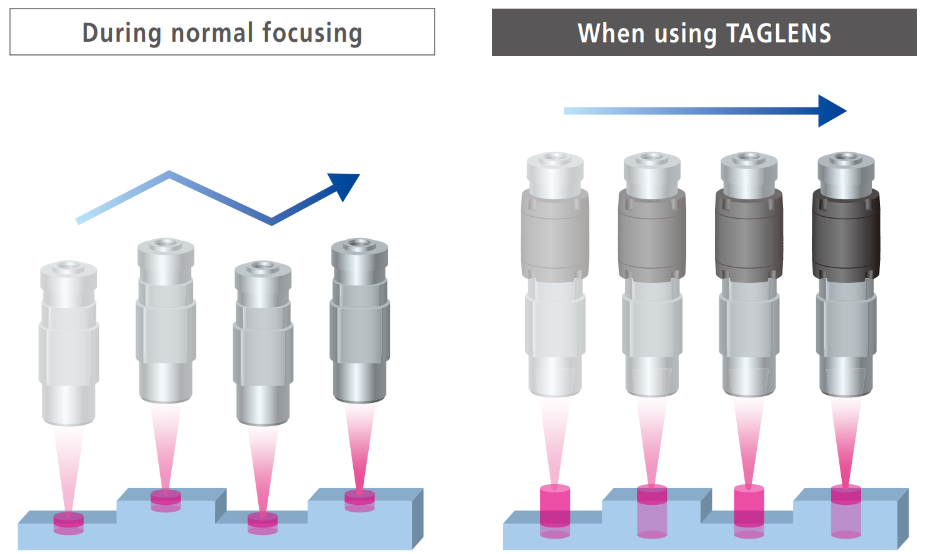

Multi Focus

Up to 20 cross-sectional images at arbitrary heights can be captured simultaneously

・ A focused image in any specified Z-position can be captured without mechanical drive system within the observation range at an extended depth of focus.

・ Multiple images focused in given Z-positions can be captured.

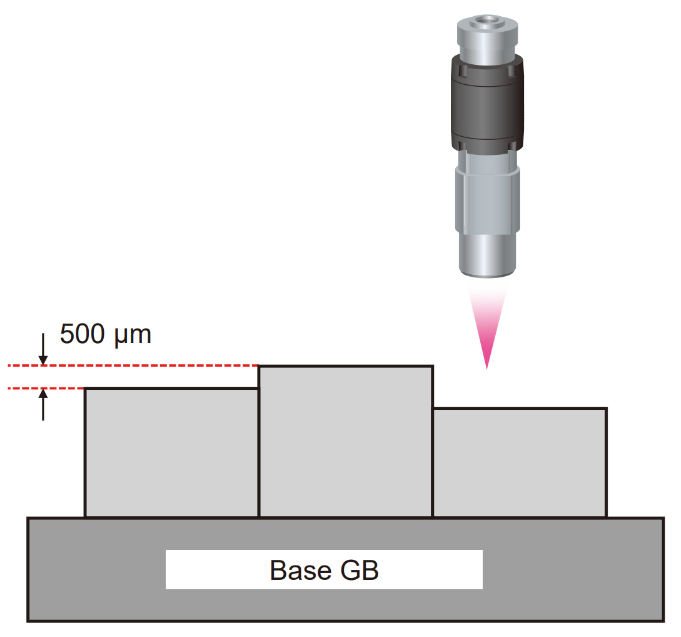

TAGLENS-3D/Z-Adjust

3D shapes can be captured without mechanical action in the height direction

・ Select Z-Adjust with dedicated chart or Nominal Z-Adjust with theoretical values.

・ Using the height information obtained from Z-Adjust/Nominal Z-Adjust for TAGLENS-3D, point cloud data can be generated.

*Z-Adjust can be used only in combination with VMU-T1.

*3D shape data display/analysis software is to be prepared by the customer.

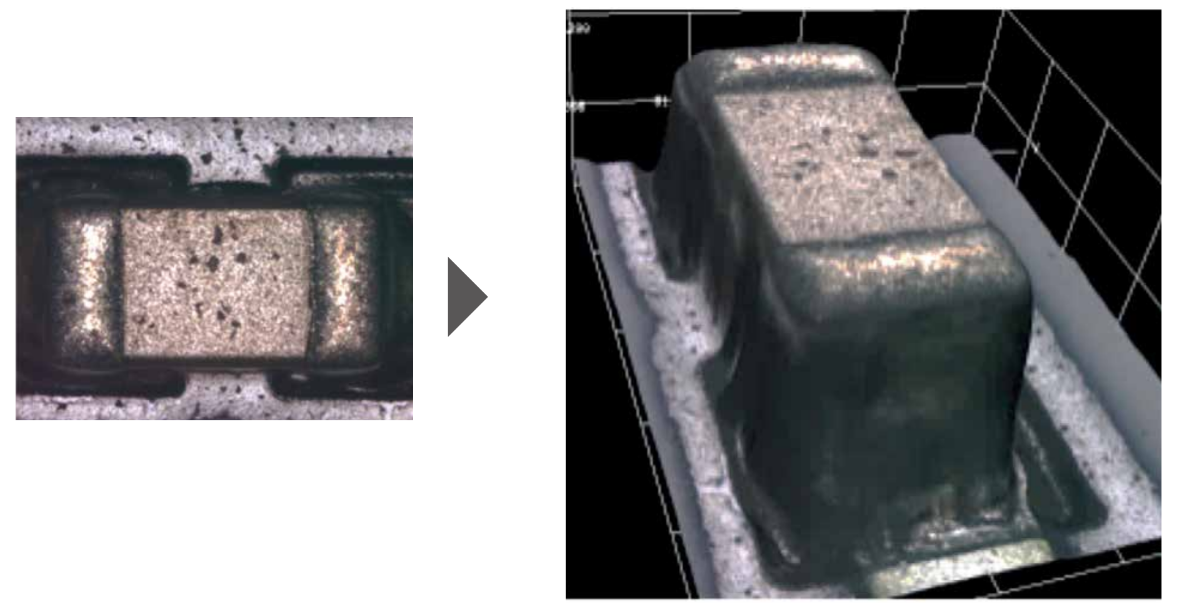

|

2D image composite from Z-stack and 3D image

|

Dedicated Chart for Z-Adjust

|

Auto Focus

High-speed focusing without mechanical action

・ Contrast peak position is determined from the images captured during the focal sweep.

・ After image acquisition, It takes only 10 ms to determine the focus position.

*With Mitutoyo demonstration system

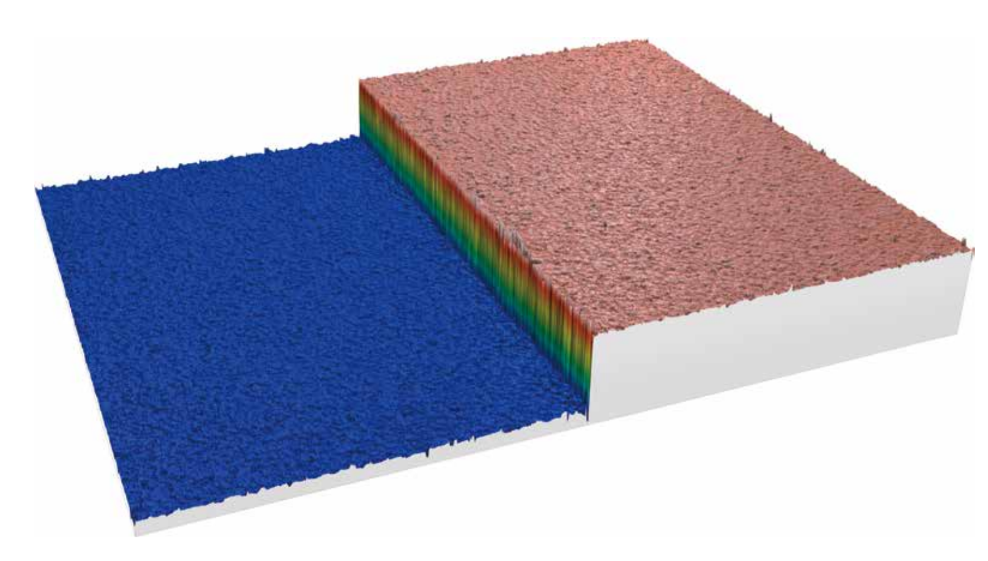

Focus Stacking

All-focused images generated from multiple cross-sectional images

・ Contrast peak position is extracted and synthesized from images captured while changing focal position (image stack).

・ After obtaining the image stack, output to other companiesʼ focus stacking software is also possible.

*Image upload file type varies by company specifications

|

Target workpiece: Step 1 mm

All-focused image |

Mixed Image

Up to 3 cross-sectional images can be mixed for display within one frame

・ Multiple height observation with TAGLENS at camera maximum frame rates.

・ Ideal for observation targets requiring different brightness, as multiple pulsed light sources can be exposed within one frame.

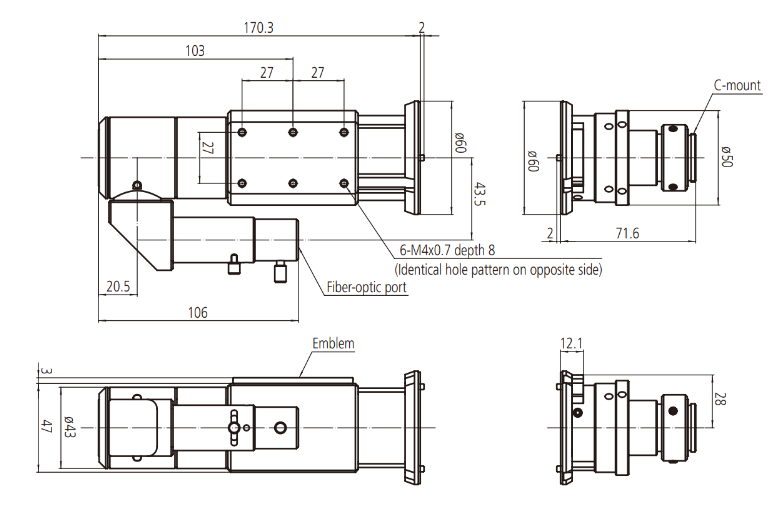

DIMENSIONS

|

TAGLENS-T1

|

<Controller> Pulsed Light Source PLS

|

The high-speed shooting of a costly crash test is successfully completed at one try thanks to a large depth of focus.

The high-speed shooting of a costly crash test is successfully completed at one try thanks to a large depth of focus.

Allows inspection of a workpiece with the camera mounted on a robot arm.

Allows inspection of a workpiece with the camera mounted on a robot arm.